- Infrasync Technology Services

- Posts

- Infrasync Newsletter #8 - Theory of Constraints ...for Water Systems

Infrasync Newsletter #8 - Theory of Constraints ...for Water Systems

What if I told you that implementing new technology into a water system can be simple? Or if not simple, at least most of the work has already been done.

This is possible by using the Theory of Constraints. This approach was first put forth by Eliyahu Goldratt in 1984 in the book The Goal. The theory states that for a system there is a defined goal and a series of constraints preventing the system from reaching that goal. This is typically equipment, people, or processes.

Apply this to a utility system, there are several high level goals and dozens of more intermediate goals. For example if the goal is affordable drinking water then you can look at the major areas of operating expenses such as energy, chemicals, labor, etc and where those can be improved. Lets do an example.

The end goal is affordable drinking water. This can be measured by cost to obtain the water, cost to treat the water, and cost to distribute the water. This example will focus on the cost to distribute the water.

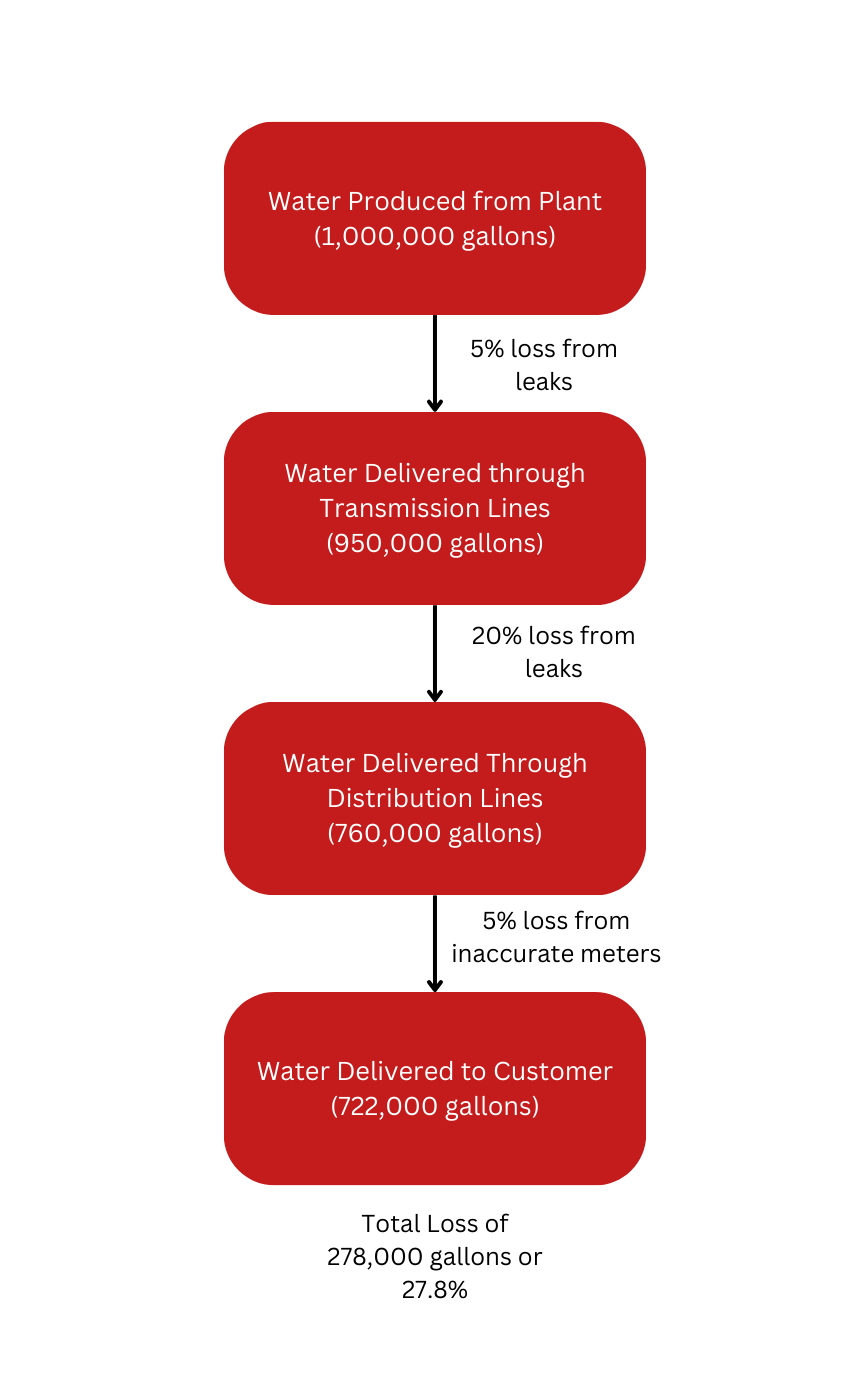

Quickly map out this chain, high level is best to start. Details can be added as needed. There is each component in the chain and then the connecting pieces. This is a quick example for drinking water loss:

Systems Approach to Water Loss

Based on this quick graphic, where does it make sense to focus the efforts? It should be the Water Delivered through Distribution Lines. That is accounting for a loss of 190,000 gallons!

Ok now that the first step of identifying the constraint is done. What do you do next? Take a deeper dive into that one issue through the lenses of equipment, people, and processes.

This is when it can get tricky, where do you improve? What do you focus on? Talking to a utility or someone else who has a better handle on this system helps. Ultimately, it’s up to you at the utility to determine where to focus. Brainstorm ideas and decide what one or two things to implement that will move this forward.

Equipment Idea –– Adding some acoustic leak sensors would allow the utility to better find leaks as they arise instead of waiting several months until they get bad enough to notice.

People Idea – Dedicate someone from engineering or operations to find and implement best practices for leak detection and repairs.

Process Idea – Set up the leak repair process so when leaks are found there is a 3rd party that fixes them in 72 hours.

Common Components to Improve

One of the big advantages a utility has is their stable operations from day to day. Things do not change quickly in a utility! While this can make it difficult to implement new things this also has a great advantage of a stable and consistent working environment. You can try one or two things at a time, track those results, and see where the real impact was. If successful great! If not, no worries as you can adjust something else until you find that critical constraint.

Want to get serious about this? It may be a good idea to get outside the water industry for a bit, even if just a book. This approach is explained very well by Goldratt in his book. Links to Wikipedia and the book on amazon are below.

Make sense to connect?

Are you working to help your utility or technology company take the next step forward? I enjoy connecting with others who share the same goals and passion of using technology to solve water utility challenges. If you want to talk through a challenge or share something interesting your team did please shoot me a note at [email protected] or schedule a 15 minute call here.